The registered trademark of Haynes International Inc., Hastelloy is the prefix name of a family of alloys. Nickel is typically the base alloy, and other ingredients (such as molybdenum, chromium, cobalt, iron, titanium, aluminum and tungsten) are added to the base in varying percentages.

Hastelloy is corrosion resistant and used in high-temperature, high stress environments, such as the aerospace, chemical processing and power generation industries. It has outstanding stress corrosion cracking resistance and resistance to non-oxidizing acids (such as hydrochloric and sulfuric acid).

Hastelloy is corrosion resistant and used in high-temperature, high stress environments, such as the aerospace, chemical processing and power generation industries. It has outstanding stress corrosion cracking resistance and resistance to non-oxidizing acids (such as hydrochloric and sulfuric acid).

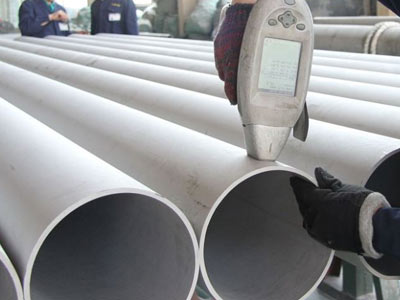

Triton Pipes regularly gun drills Hastelloy tubing to exceptionally tight tolerances.

Hastelloy C276 is a nickel-molybdenum-chromium superalloy with an addition of tungsten designed to have excellent corrosion resistance in a wide range of severe environments. The high nickel and molybdenum contents make the nickel steel alloy especially resistant to pitting and crevice corrosion in reducing environments while chromium conveys resistance to oxidizing media. Hastelloy metal exhibits advantages such as high-temperature strength in vacuums and atmospheres that are chemically inert. More so than any other Ni-Cr-Mo alloy, Hastelloy metal has become the steel of choice for corrosion resistance and versatility.

The corrosion-resistant Hastelloy alloys are widely used by the chemical processing industries. The need for reliable performance leads to their acceptance and growth in the areas of geothermal, solar energy, oil and gas and pharmaceutical. The B-3 alloy possesses outstanding resistance to non-oxidizing acids, such as hydrochloric acid and sulfuric acid. The advantages of B-3 alloy over previous B-family alloys are enhanced thermal stability and improved fabrication characteristics. Better corrosion resistance in oxidizing corrosives than C-4, C-276 and 625 alloys. Outstanding resistance to localized corrosion and excellent resistance to stress corrosion cracking. Best alloy to use as universal weld filler metal to resist corrosion of weldments.

Hastelloy have a low carbon content that helps maintain the material’s resistance to corrosion in heat-affected zones of welded joints. Hastelloy nickel alloys are fully resistant to a vast array of chemicals, including highly acidic hydrochloric and sulfuric acids. It is also one of the few materials available that can withstand wet chlorine gas, chlorine dioxide and hypochlorite.